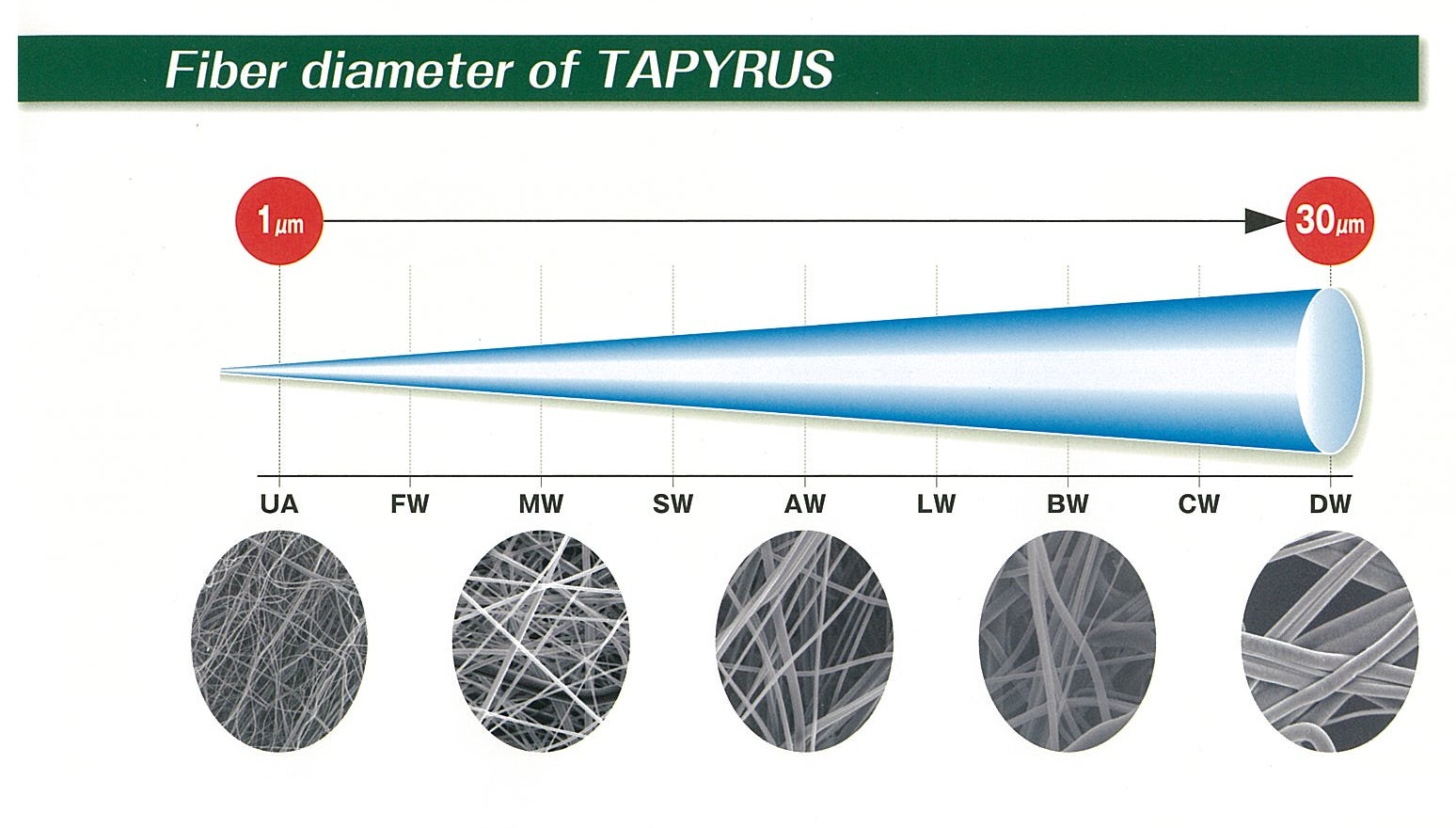

- Fiber diameter

- controllable as wide as from less than 1μm to a few dozen μm

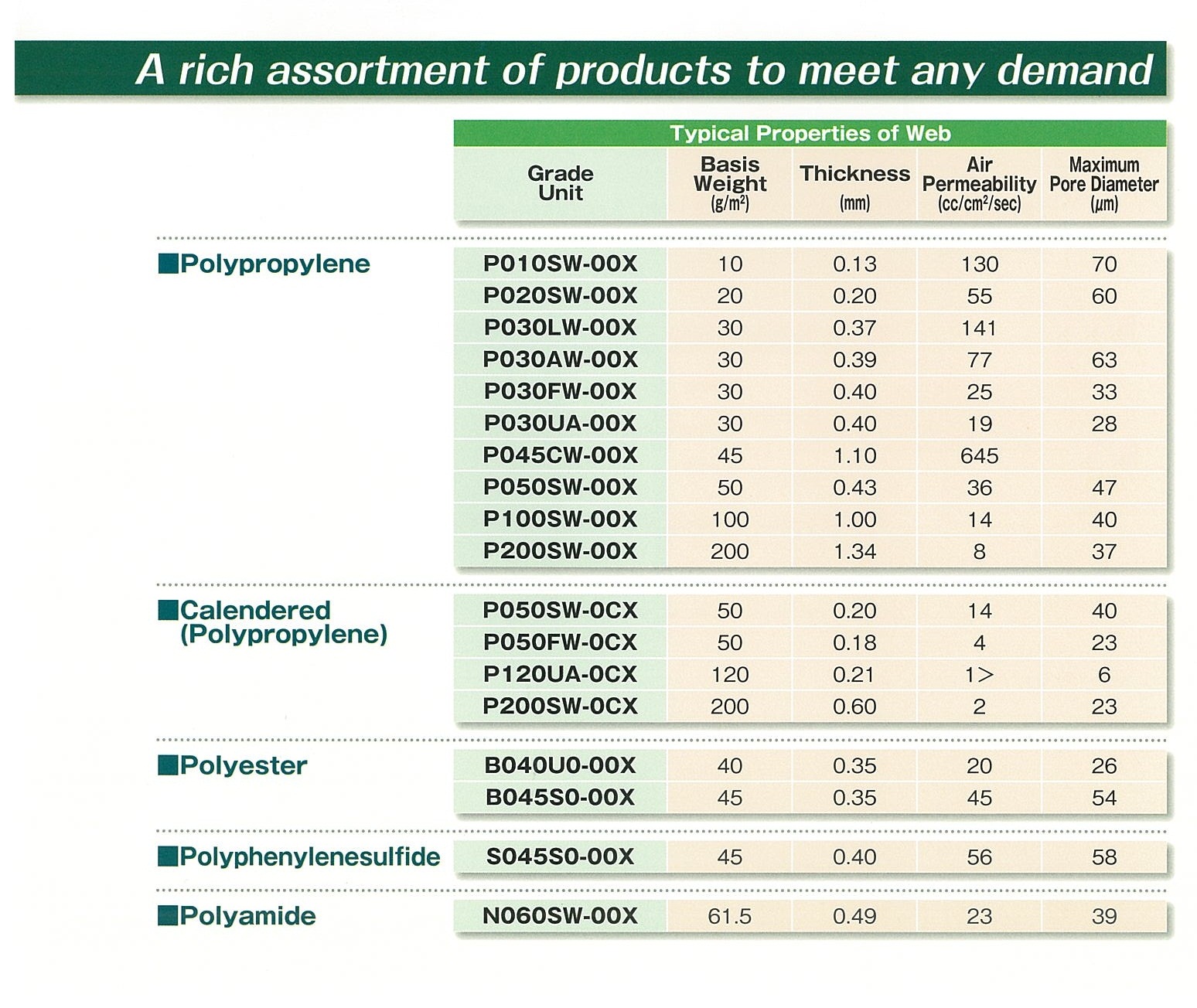

- Basis weight

- controllable as wide as from approx. 7g/㎡~4 0 0g/㎡

- Pore size

- porosity with as small as from a few to 100μm size, superior filter performance with its porous nature.

・Made of fine fiber uniformly and isotropically dispersed

・Excellent texture, softness and drapability.

Variety of raw material resin

Any thermoplastic resin can be used to make meltblown nonwoven.

The followings are the raw material resin which we have used for Tapyrus products.

- Polypropylene

-

- Good in chemical resistivity, water repellency, and electrical insulation.

- As it stands against autoclave sterilization, it can be used for the food services, drinks, and industrial goods of medical use.

- Relatively inexpensive and most widely used as raw material of Tapyrus products.

- Polyester

-

- Good heat resistivity (m.p. 220~240℃) and good oxidative degradation resistivity.

- Appropriate for secondary processing like as impregnation in the aqueous solution.

- Polyamide

-

- High water absorption capacity having amide group.

- Good heat resistivity (m.p. approx.. 225℃) and good chemical resistivity.

- Poly Methyl Pentene

-

- Good heat resistivity (m.p. approx.. 230℃), and good in chemical resistivity and electrical insulation as it is a kind of polyolefins.

- Poly Phenylene Sulfide

-

- Good heat resistivity (m.p. approx.. 285℃)and good frame retardancy.

- Good chemical resistivity against any solution except for hot concentrated nitric acid.

- Poly Lactic Acid

-

- Bioplastic not derived from fossil resources.

- Biodegradable and environmentally friendly resin to be decomposed to carbon dioxide and water by microorganism in the end.

※We have lots of manufacturing experience for many other thermoplastics.