To meet customers requirement, we not only manufacture nonwoven, but also produce calender-processed products and composites from meltblown and other nonwoven materials.

Manufacturing process of meltblown nonwoven

Meltblown process is categorized as a melt spinning method, which can obtain the product directly from raw material resin.

① The raw material polymer resin is heated to be melted. ② The molten polymer is blown from the nozzle with hot air to obtain a very fine fiber.

The molten thermoplastic polymer is extruded as a strand from the die tip nozzle, having hundreds to more than a thousand capillary per meter, with high velocity hot air.

The fibers are entangled and cohesively stick together to form self-bonded fine fiber nonwoven without any binder.

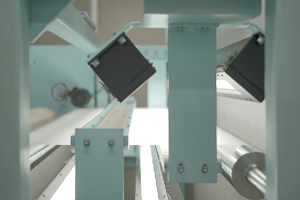

Uniformity of the web is strictly monitored by the inspection devices such that no contamination of foreign matters occurs.

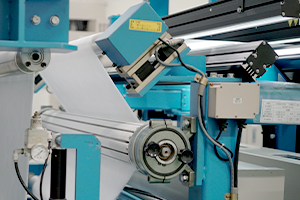

The web is wound around the roll at the preset width and length.

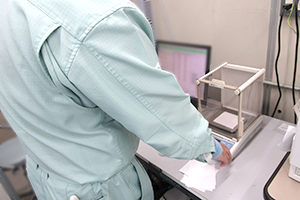

A variety of quality measurement is conducted for the rolled-up web.Quality Control

In accordance with the customers’ request, the slitting and calendering process is followed.

The roll product of nonwoven is stored in the warehouse, and timely delivered to the customer place.

History of meltblown process

R&D of meltblown process started in 1940’s. The first kind of microfiber based on the melt-blow principle was made of inorganics.

On the other hand, R&D work of the organic microfiber started in 1951 at a laboratory of US Navy, which successfully established the technological fundamentals of meltblown process. Exxon then inherited this technology, and started R&D effort in 1965 to manufacture nonwoven microfiber with polypropylene (PP). However, Exxon withdrew from it in 1973, and provided the technology license to several ventures for commercialization.

Hence, Exxon’s nonwoven fiber technology of PP is yet a mainstream of the meltblown process.

In Japan, Tonen Sekiyu Kagaku (now Tonen Kagaku GK) which was then an Exxon affiliate company in Japan, inherited this technology and commercialized the nonwoven product.Tonen Tapyrus Co. Ltd. (a predecessor of Tapyrus Co. Ltd.) further inherited the nonwoven business and technology.